EPOXY QUICK FIND LINKS - COMPREHENSIVE

EPOXY RESOURCE WEB SITES - CLICK HERE

The Expert's Best Picks:

a.ka. "Boat Epoxy"

MARINE EPOXY: The Very Best Web Products - Best Marine Epoxy

RATED BEST: Marine Epoxy (boat epoxy) - top rated

Paul Oman - MS. MBA

A.K.A. “Professor E. Poxy”

epoxies since 1994

Member: NACE (National Assoc. of Corrosion Engineers)

SSPC (Soc. of Protective Coatings)

PRODUCT NAME ----- Basic No Blush (tm)

Professional Marine Epoxy Resin / NON BLUSHING! /

This product is featured on the GreatThings4u.com website

Another great marine epoxy page EVERYTHING EPOXY SITE

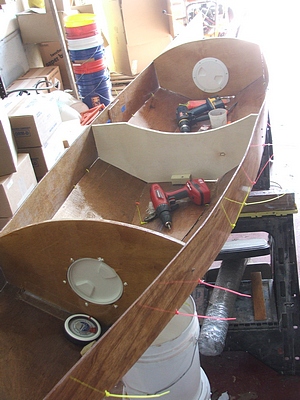

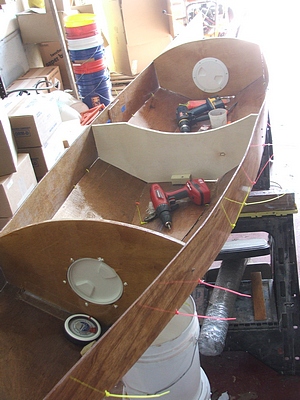

marine epoxy boat building

| Order this product by calling 603-435-7199 anytime or order online using this link: EPOXY NOW |

SELECTION CRITERIA ----- This product received its BEST rating for several reasons.

Basic No Blush is a formulated epoxy. Only 4 or 5 marine epoxies are formulated epoxies. This means their manufacturer begins with the raw resins and curing agents made by the major chemical companies and then adjusts/adds to them to formulate their marine epoxy. The other marine epoxy vendors (the low price guys) are 'barrel to jug' repackagers. They simply order jugs of material from the major chemical companies and pour those resins directly into jugs for sale to end users.

Price - Basic No Blush marine epoxy is about half the price of the other formulated epoxies and about the same price as the repackaged marine epoxies (sometimes even much less). This is possible because the company doesn't use distributors or agents, has no 800 phone number, slick printed catalogs, or trade show booths. These savings get passed onto the customer when they purchase from the on-line store.

Basic No Blush is a 'non blushing' epoxy. The competitor's primary epoxies all can produce as waxy film on the epoxy surface when the epoxy cures called "blush". This product uses more expensive curing agents that do not blush.

Basic No Blush marine epoxy is offered with a slow summer curing agent for use in hot weather and a fast winter curing agent for use in temperatures just above freezing. This makes it ideal for winter boat building projects in unheated spaces in the northern states.

cedar strip MARINE EPOXY RESIN kayak

|

Why Basic No Blush (tm) epoxy is the BEST in its class: 1. A formulated blended resin system (not repackaged raw chemicals) 2) Uses NON BLUSHING curing agent for blush free results 3) not too thick, not too thin, not too brittle - ever see an epoxy surface with millions of tiny cracks? It is brittle, repackaged (see #1) not formulated epoxy 4) the only marine type epoxy with bubble breakers for superior flaw free finishes and uniform properties and appearance and allows for thicker, multiple layers with better clarity 5) the only epoxy adduct marine type epoxy for superior enhanced properties (standard cure only) 6) strong user support / feedback 7) 24/7 support email marineepoxy@gmail.com 8) less expensive than the other formulated epoxies which still don't have many of the advantages listed here |

| THIS PRODUCT | xx | EMAIL US | xx | |

| air shippable | cycloaliphatic system | |||

| no nonyl phenol | epoxy adduct system | xx | ||

| multi curing agents | xx | bulk pricing | xx | |

| solvent free | xx | no Calif. sales | ||

| 2 part epoxy | xx | 2 part poly | ||

| apply underwater | bubble breakers | xx | ||

| favorite(s) product list | xx | data sheets | xx | |

| PACKING - jugs/bottles | xx | PACKING - cans | xx | |

| find in non marine cat | xx | find in marine catalog | xx | |

| PRICES/ind/commercial | xx | PRICES/marine section | xx | |

| BUY online | BUY online | xx | ||

| home page | xx | contact page | xx |

|

Epoxy Crazing Notice/Warning |

|

There are two types of Marine Epoxy Vendors: 1) discount, bulk, REPACKAGERS who simple buy drums of raw resin and raw curing agent(s) from the big chemical companies and fill plastic jugs for resale; 2) FORMULATORS take the raw epoxy chemicals add to them to enhance and improve the raw "moonshine" into a "fine whiskey". Learn more repackagers/formulators. Our Basic No Blush (tm) is a formulated non blushing epoxy by Progressive Epoxy Polymers, Inc. (homepage). that includes additions for reduced brittleness and exclusive (only we have it) bubble breakers for a more perfect looking finish. Basic No Blush is the least expensive of the formulated epoxies and considered the best marine epoxy by many ex-users of the other formulated epoxies. REPACKAGED EPOXY WARNING: Over the years I have seen and had reports of non-formulated, raw resin/cure epoxies (which are extremely hard and brittle) becoming crazed with millions of cracks (like shattered safety glass) in outdoor settings that experience big changes in temperature. Formulated epoxies all seem to be 'fixed' to allow for this expansion and contraction without cracking by making them less brittle and better able to handle internal stresses. |

|

Marine Catalog ///// Stitch n Glue ///// Epoxy Only Google Search ///// Epoxy Guru Help Site ///// Marine Boat Epoxy Etc. Links |

| "I've been using the Basic No Blush epoxy on all my own stuff, and using up all the West epoxy on most customers boats. When the West is finally gone I'll only be using your epoxies. Good stuff. I'm rebuilding an old Rybovich so a big order in the future..." Patrick (comment with on-line order 9/4/07) ---- Order No Blush online |

PRODUCT DATA SHEET (PDF) ----- CLICK HERE best marine epoxy .

WEB INFO SHEET ----- CLICK HERE best marine epoxy data sheet .

MSDS ----- CLICK HERE basic no blush marine epoxy- boat epoxy msds .

PURCHASE LINK ----- CLICK HERE buy Basic No Blush marine epoxy here .

No Sales Tax applied. Save Money, you're shopping in Tax Free New Hampshire

| Order this product by calling 603-435-7199 anytime or order online using this link: EPOXY NOW |

OTHER LINKS ----- Huge director of boat/marine related links CLICK HERE internet boat epoxy links

How to evaluate marine epoxy CLICK HERE how to select marine epoxy for boat building and boat repair

Visit The Marine Epoxy Everything Guide (click here)

site co-sponsors:

OUR FAVORITE ONLINE EPOXY VENDOR SITES

Top two epoxy vendor sites on the Internet - #1 (huffnpuff.us) and #2 (epoxyproducts.com)

MOBILE FRIENDLY everything-epoxy web site (with links back to "full screen" web sites) CLICK HERE

|

"OK...thanks for the personal touch. And for such an informative website. The navigation took me a while to grasp, but I really appreciate all the credible, helpful information you provide. This is my 3rd or 4th order over the years and I give you a A or A+ grade on all of it. I'm a nit-picking former Polaris nuclear missile targeting and firing guy so you don't get a good grade from me unless you are on target!" -- Dave 7/14 call for info/help/ordering anytime 603-435-7199 |

|

PARTIAL DATA SHEET |

BASIC NO BLUSH (tm) |

|

Boatbuilding Fiberglass Laminating Pebble Stone Surfacing

|

Solvent-Free Easy 2:1Mixing Ratio Contains no carcinogens Medium Viscosity Three Different Curing Agents

|

|

STANDARD PRODUCT DESCRIPTION

|

Basic No-Blush™ is a 100% solids, marine grade epoxy coating system designed for general marine/ boating applications. It will not blush or water spot under normal conditions. It is available with three different curing agents, a fast cold weather (a slightly yellow curing agent), our standard clear curing agent, and a thicker, amber colored slow warm weather curing agent. The standard cure version is also widely used for resealing epoxy/pebble flooring systems.

The slow summer curing version is ‘viscosity adjusted’. Because epoxies become thinner (less viscous) in warmer weather, the summer curing agent has been thickened to approximate the viscosity of the standard No-Blush epoxy at approximately 70°F.

|

| USES

|

Creating and maintaining pebble/epoxy decks Boatbuilding/Repair

|

| FEATURES

|

Excellent chemical resistance Convenient 2 to 1 ratio by volume ( 1 to .422 by weight) base/cure - Standard cure Superior adhesion to cold, damp surfaces

|

| VISCOSITY

|

Approximate viscosity at 72°F: Standard/Winter Summer Part A: 900 cps 900 cps Part B: 175 cps 4,500 cps Mixed: 600 cps 2,000 cps

|

|

PHYSICAL PROPERTIES

|

COMPRESSIVESTRENGTH .......... ASTMD695 9,500 psi /9,200 psi (STANDARD/SUMMER)

TENSILESTRENGTH.................... ASTMD638 6,200 psi /8,600 psi

ABRASIONRESISTANCE CS-17WHEEL, 1 kg LOAD ............ ASTMD4060 0.20 gm loss /0.20 gm loss

WATERABSORPTION.................. ASTMD570 0.16% /0.16 % (2 hour boil)

FLEXURALSTRENGTH................ ASTMD790 5,500 psi /5,500 psi

SHORE D HARDNESS ................. ASTMD2240 90 /78

HEATDISTORTION...................... ASTMD649 125°F /125° F TEMPERATURE

LAPSHEAR.................................. 2,200 psi /2,250 psi

|

| FIND COMPLETE DATA SHEET AND MSDS - CLICK HERE | |

| Order this two part EPOXY Product NOW |

|

Epoxy "Stab Brush" -- "Regular Brush" |

|

Use with products on this page |

|

buy separately or include with your order |

|

|

|

STAB BRUSH - 3 inch wide with 3/4 inch bristles. Most epoxies are too thick for a regular brush. Stab brushes allow you to push and move the epoxy around and 'stab' or poke it into cracks, voids, and corners |

| REGULAR BRUSH - 2 inch wide and extra thick with synthetic bristles. Use with varnish, paints and thin epoxies. Priced for disposable use. |

|

Find Stab Brushes and Regular Brushes in our MARINE CATALOG or in our HOME/COMMERCIAL CATALOG |

|

Goto our 3rd party storefront and purchase in the MISC SECTION |

DID YOU KNOW...

Epoxy coatings are used because of their

outstanding chemical resistance, durability, low porosity and strong bond

strength.

Epoxies consist of a ‘base' and a ‘curing' agent. The two components are mixed in a certain ratio. A chemical

reaction occurs between the two parts generating heat (exotherm) and hardening the mixture into an inert, hard

‘plastic'.

Epoxies yellow, chalk (or more commonly least lose their gloss), in direct sunlight (UV). The yellowing can

be a real problem. For pigmented epoxies select colors that are dark or contain a lot of yellow (such as green).

Even clear epoxies will yellow and cloud up. Often epoxies are top coated with latex or urethanes that will retain

their color and attractive gloss. This is particularly true if color coding or matching company colors is important.

Epoxies will harden in minutes or hours, but complete cure (hardening) will generally take several days. Most

epoxies will be suitably hard within a day or so, but may require more time to harden before the coating can be

sanded.

By their nature, epoxies are hard and brittle. Additives can be added to epoxies that make them less brittle,

but generally at the loss or reduction of other positive epoxy properties such as chemical resistance.

Other clues of cheap epoxies include ‘induction time' (after mixing the two components the mixture must sit

for several minutes to ‘self cook' before being applied).

The best time to recoat epoxy is within about 48 hours after the initial coat. Because epoxies take days to

reach full cure, a second coat applied shortly after the first coat will partially fuse to the first coat rather

than forming a simple mechanical bond.

End users can thicken epoxy with many things, Tiny glass spheres, known as micro-spheres or micro-balloons

are commonly used. Besides thickening, their crushable nature makes sanding the hardened epoxy easier. On the downside,

they work like tiny ball bearings, resulting is sagging and slumping. Another thickener is fumed silica (a common

brand name is Cabosil (tm)) which looks like fake snow. About 2 parts fumed silica with one part epoxy will produce

a mixture similar in texture and thickness to petroleum jelly. Micro-spheres and fumed silica can be combined together.

Fisheyes are areas on a painted surface where the coating literally pulls away for the substrate leaving a coatingless void or fisheye. Often fisheyes are caused by surface contaminants such as a bit of silicon, wax, or

oil. I have also seen them on clean plywood where epoxies paints have been used as sealers and the problem might

be due to uneven saturation (soaking-in) of the epoxy into the wood. Surface tension plays a big part in fisheyeing.

There are some additives that can be mixed into the epoxy that will reduce surface tension. Likewise, on wood,

applying several coats of solvent thinned epoxy, instead of one coat of unthinned epoxy, seems to work well. Applying

a thick coat of epoxy over a contaminated fisheye surface will bury the fisheye but expect the coating to peel

away in the future. As a rule of thumb, always suspect some sort of surface contamination as the primary cause

of fisheyeing.

Adding a bit of solvent to a solvent based or solvent-free epoxy is something that most manufacturers would

not officially approve of and something that might not work with all epoxies. However, it can be done (unofficially)

with the epoxies I deal with. Adding solvent to these epoxies will: 1) thin them out; 2) increase

pot life; 3) allows

them to flow off the brush/roller a bit more smoothly; and 4) perhaps allows them to ‘soak-in', penetrate, or may

be soften, the substrate just a little bit. Not change is visible in the epoxy unless 12% or greater solvent is

added. With that amount of solvent, the epoxies no longer cure with a glossy finish.

It is best to use epoxies with a mix ratio close to 1 to 1 as opposed to something 4-1, 5-1, etc. because errors

in the mix ratios can be more pronounced with the latter. That said, no matter what the mix ratio is, some epoxies

are more forgiving of mix ratio errors than others. One ‘trick' of epoxy vendors with odd or very sensitive mix

ratios is to sell calibrated pumps that disperse the epoxy components in exact amounts.

How Thick? How thick should your coating be? Economics play a major role in determining how much coating to apply. One U.S. gallon contains 231 cubic inches. That's only 1.6 cubic square feet of surface at one inch thick and that's also assuming a solvent-free product. If the product is 25% VOC (i.e. 25% solvent) then dry thickness/coverage will be 25% less. Again, assuming a 1/4 inch thick coating (250 mils) maximum coverage will still be only 6.4 square feet per gallon. A solvent-free (100% solids) epoxy coating applied at 16 mils will cover 100 square feet per gallon (note: the wall paint in your office is probably 2-4 mils). While thick coatings sound like a good idea, they use so much product that they must be made very cheaply so that coating 1,000 or 10,000 square feet can still be done at a competitive price. A high quality, fairly expensive product with a coverage rate of 100 sq. feet or more per gallon, on the other hand, will have a low enough cost per sq. foot to provide both economy and top quality.

|

ONLINE PRODUCT CATALOGS PROGRESSIVE EPOXY POLYMERS, Inc

A COMMERCIAL - INDUSTRIAL -

PROFESSIONAL PRODUCT

You won't find these products, or products like it, in

a general purpose, mass market, consumer, DIY, box store or flashy

marketing company website.

|

|||

|

ONLINE STORE Purchase Here ------ or CALL 603 435 7199 ------ HOME PAGE |

|||

|

Marine Catalog |

|||

* home

page of marine catalog section (blue background)

|

|||

| Section One MARINE - CLEAR EPOXIES Section Two FILLERS THICKENERS ADDITIVES Section Three THICKENED EPOXIES - EPOXY PUTTIES, ETC. Section Four EPOXY PAINTS (barrier coats) Section Five URETHANES AND NON-EPOXY COATINGS Section Six NON-SKID DECK COATINGS Section Seven MARINE REPAIR PRODUCTS Section Eight MISC. MARINE PRODUCTS |

|||

|

MASSIVE BOAT HOW TO - ISSUES - HELP WEB LINK SITE |

|||

|

Residential / Commercial / DIY Catalog |

|||

* home

page of residential/commercial catalog section (brown background)

|

|||

|

Section A EPOXY PAINTS Section B FLOOR EPOXIES (regular and non-skid products), SEALERS, ACCESSORIES Section C THICKENED EPOXIES - EPOXY PUTTIES, ETC. Section D CLEAR EPOXIES Section E NON-EPOXY PAINTS COATINGS SEALERS Section F MIX-IN ADDITIVES Section G OTHER PRODUCTS Section H SURFACE PREPARATION PRODUCTS Section I MISC. ACCESSORIES |

|||

|

WEB EPOXY FLOOR ISSUES LINKS SITE --- WEB EPOXY REPAIR LINKS SITE |

|||

|

top selling favorite products for your every need Buy Talk Chat Support EMAIL or 603 435 7199

American manufactured, distributed, and sold epoxies and coatings. Your business helps small American Family Businesses - Thank You! |

need to learn more about epoxies??

--- visit these third party sites ---

(EVERYTHING-EPOXY.INFO --- Intro to basic epoxy resin types )

also visit the EPOXY GURU

MARINE EPOXY: The Very Best Web Products - Best Marine Epoxy

RATED BEST: Marine Epoxy (boat epoxy) - top rated

|

HELP IMPROVE THIS PAGE Your comments, suggestions, contributions and insights about this web page are appreciated. Any pictures, product or page feedback and suggestions to help future product users or page readers is win-win for everyone. Please click on the email address below to send us your remarks, and thank you for your response. |

|

email us at: IMPROVE THIS PAGE |

#####